Experienced sea captain, Abdulla Mohamed Ibrahim,founded his trading company in 1981 to serve the growing demand for modern marine technology in the United Arab Emirates.

Over the years, he has navigated the company through a period of intense growth and secured regional distributorships for leading international brands across multiple sectors from marine and aviation navigation to water sports, outdoor recreation and fitness.

AMIT Marine Services has been an industry player and the customers’ preferred choice for marine and diving products and services since 1981. Established and based in the UAE, the entity offers customized, expert solutions in Marine Equipment and Services, and is honed to cater to the Commercial Maritime Industry across GCC and Asia. Visit our website to learn more.

AMIT RETAIL is a one-stop shop for globally renowned Outdoor Adventure brands in the UAE. Brands participating in the warehouse sale include Garmin, Tacx, Atomic, Bare, Yamaha, Stahlsac, Zeagle, Oceanic, Omer, Blue Sea, Hella Marine, Plastimo, Subgear, Sharkskin, Seac, Scubapro, Riffe, Palantic, Light & Motion, Gull, Epsealon, Fifth Element, AB Biller, Big Mouth and Wow.

Established in 1985 in the UAE, AMIT Real Estate has been at the forefront of UAE’s Real Estate market, delivering Residential, Commercial & Industrial properties across UAE and Thailand. Customer satisfaction and relationship building are of paramount importance; hence high-quality standards are applied to all property lending transactions. Visit our website to learn more.

AMIT Engineering always guarantees authentic and satisfactory service to all our clients. The goal is to provide high-quality customer service. When you are sailing on the water it is of utmost importance that your ship’s diesel engines operate properly.

For seamless operation, a reliable partner such as AMIT Engineering is indispensable. With a commitment to regular maintenance and prompt response to unforeseen events, AMIT Engineering offers an extensive stock of OEM spare parts and engine overhauls. As well as expert repairs and routine maintenance and support plans. Count on AMIT Engineering for the utmost professionalism in safeguarding your diesel engine’s performance.

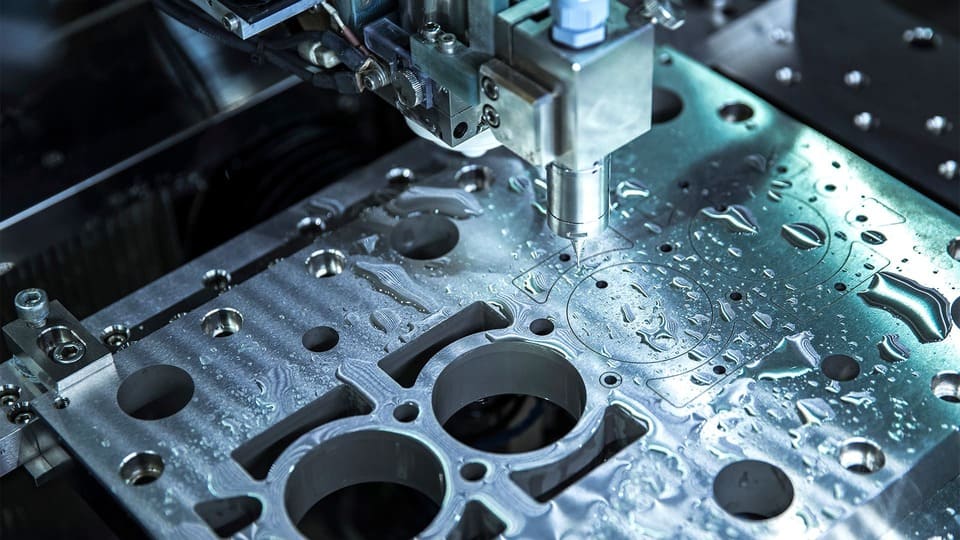

With the advancement in technology – Testing and Measuring methods have advanced significantly. With the use of borescopic testing, compression testing, performing sea trials, and engine diagnostics, we can identify and troubleshoot any probable issues that may occur. These testing are performed with in-depth analysis within engine parameters and help to diagnose any faults or issues within the engine. By utilizing these advanced techniques, we can ensure that our engines are functioning at their optimal level, which leads to increased efficiency and reduced downtime.

In this region, introducing the latest Ultratechno ACM-2000n is solely available in our facility which is especially useful for removing tightly adhered contaminants from intricate items with blind holes, cracks, and recesses.

To clean heavy-duty diesel engines, having an effective and efficient cleaning method is decisive. At our facility, we have a state-of-the-art customized modern high-frequency ultrasound cleaning method that is designed to agitate the cleaning solutions, which even removes the most stubborn contaminants (dirt and oil). Our machine is equipped with several advanced features, including ARF noise reduction, triple thermal insulation, and protected ceramic heaters, which ensure that the cleaning process is not only effective but also safe and competent. Additionally, the machine has a powerful 28kHz ultrasound capability that can easily penetrate and remove contaminants from even the most challenging areas. Our machine also utilizes LFS oil separation and FOE floating oil extraction, which ensures that the cleaning process is eco-friendly and helps to reduce waste. Overall, our customized high-frequency ultrasound cleaning method is the ideal solution for Marine Propulsion Diesel engines.

AMIT Engineering exclusively owns top quality Front loader, MAGIDO L240E (X53) with a Load weight of 1500 kg. This machine is designed to provide a thorough and effective cleaning process, without the use of any hazardous detergents.

Instead, the machine utilises hot wash degreasing and multi-stage wash cycles to remove even the most obstinate contaminants from the engine spare parts. The stainless-steel construction ensures that the machine is durable and long-lasting, while the top load design allows for easy access and efficient loading and unloading of the engine spare parts.

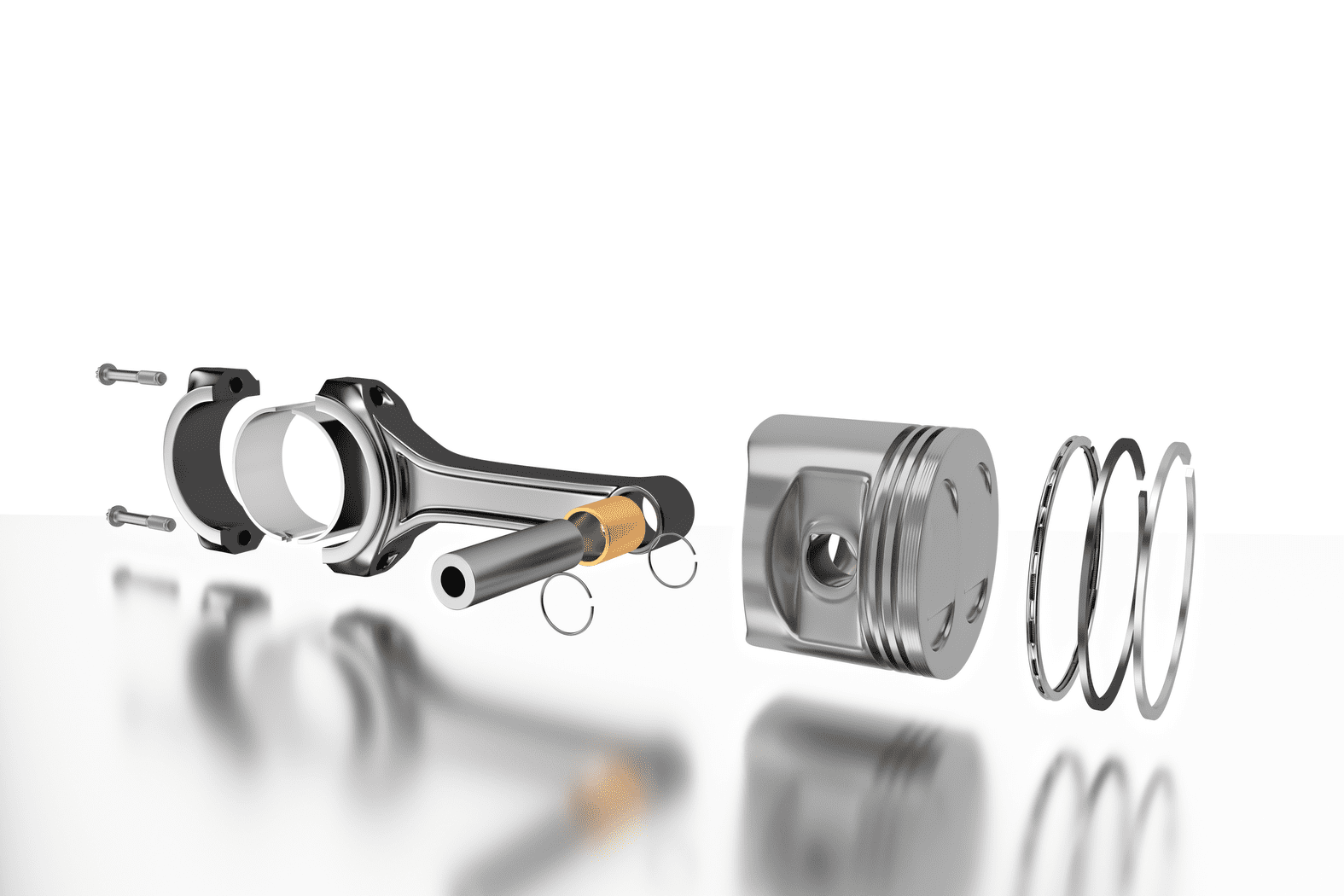

Marine engines are designed to operate in harsh environments and must be able to withstand extreme temperatures, pressures, and corrosive elements. The repair and replacement of damaged or worn-out parts, such as pistons, cylinders, crankshafts, and bearings are necessary. This will extend the lifespan of marine engines, improve their performance, and reduce downtime and maintenance costs. With the help of advanced technologies and skilled technicians, re-engineering of marine engines and machining have become more efficient and effective, ensuring safety and reliability.

A comprehensive engine health check should include a thorough inspection of the engine’s internal components, such as the oil filters, coolant systems, belts, and hoses. Additionally, regular oil and filter changes, cleaning the fuel system, and checking the electrical system are necessary steps of maintaining the engine’s performance. Adhering to a regular maintenance schedule can minimize the risk of engine failures, costly repairs, and ensure a smooth sailing experience. With AMIT Engineering annual maintenance contract – engine health checks and routine maintenances are much more affordable.

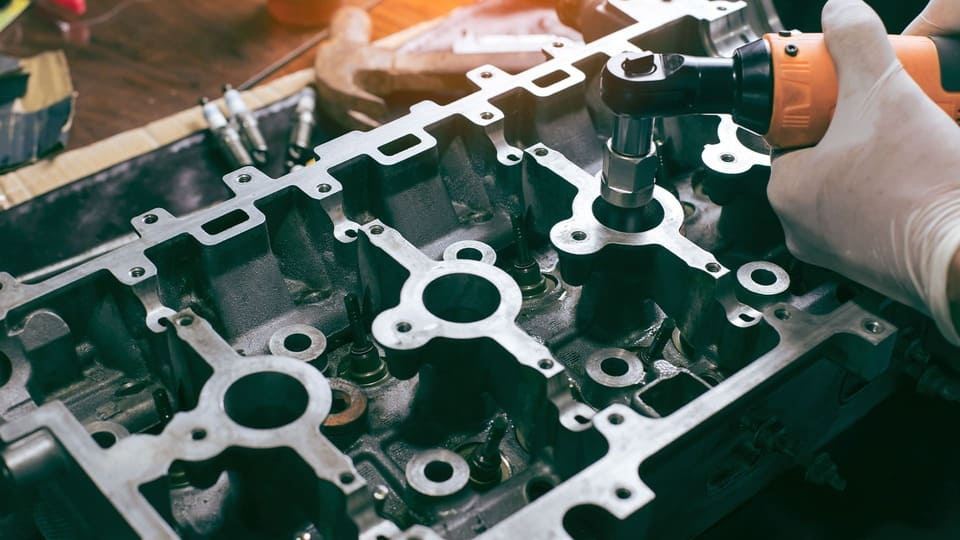

Refurbishment involves updating and upgrading the components to modernize their appearance and functionality. On the other hand, overhauling entails a complete dismantling of the vessel’s engine, replacing worn-out parts, and rebuilding it back to factory specifications. Both offer numerous benefits, such as improved fuel efficiency, increased power, and a smoother ride. These solutions also address common issues like corrosion, leaks, and electrical malfunctions. Refurbished and overhauled solutions will provide a more enjoyable and comfortable sailing experience. These are excellent solutions for our clients who are looking to enhance their boat’s overall performance and prolong its lifespan.

OEM parts are designed to fit and function precisely in the specific engine for which they were manufactured, ensuring the best possible performance and durability. As a reliable supplier of diesel engine spare parts, we have a comprehensive inventory of spare parts, including those for older and less common engine models. To ensure optimal performance and longevity, it is crucial to use high-quality spare parts. By using OEM spare parts and working with us, diesel engine operators ensure the best possible performance and longevity for the engines.

A Value Care Agreement (VCA) is a comprehensive program offered by us that includes engine or gear box upgrades, routine maintenance, and repairs. VCAs are designed to help customers maintain the reliability, efficiency, and performance of their diesel engines while reducing the overall cost. Under VCA we provide scheduled maintenance, inspections, diagnostics, as well as the repair and replacement of parts. VCAs can be tailored according to

the specific needs of the customer and the engine that can cover one or multiple engines. By enrolling in a VCA, diesel engine operators can have peace of mind knowing that the engines are receiving regular maintenance and repairs from well-trained technicians at AMIT Engineering.

When an engine breakdown occurs, it can result in revenue loss, downtime, and even safety hazards. That’s why AMIT Engineering offers 24/7 hotline support with rapid breakdown response. This service provides our customers with immediate access to trained technicians who can help diagnose the problem, provide advice, and arrange for on-site repairs if necessary. The hotline support can also provide customers with access to technical manuals, parts catalogs, and troubleshooting guides, allowing them to find the information quickly and cater to their needs immediately. By providing 24/7 hotline support with breakdown response, we can help our customers to minimize downtime, reduce repair costs, and maintain the reliability and performance of the engines.